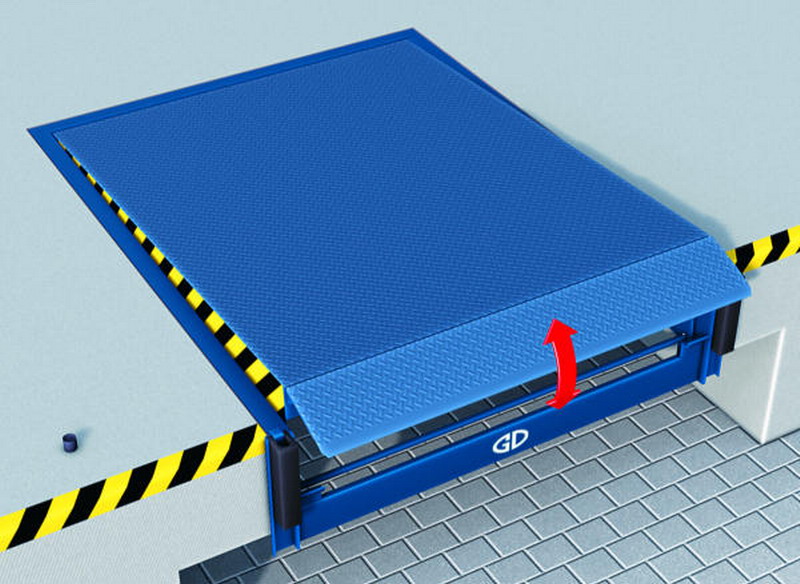

Tilting Bridge Plate Dock Levellers

Tilting bridge plate dock levellers are one of the most widely used and reliable solutions in material handling, designed to bridge the height difference between vehicles and loading ramps with varying platform heights. This ensures fast and safe movement of goods between warehouses and transport vehicles.

Key Features and Benefits:

- Compliance with Standards: These dock levellers fully comply with the EN 1398 European standard, which defines the safety requirements for loading equipment.

- Bridge Plate Design: The 400 mm protruding bridge plate ensures a secure and stable connection to the vehicle platform, minimizing the risk of accidents, instability, and potential damage to goods or vehicles during loading.

- Step-Free Connection: The design of the dock leveller creates a seamless, level connection, facilitating smooth movement of forklifts and other handling equipment.

- Installation Options: The equipment can be integrated into a concrete foundation with a built-in installation frame or installed into a prefabricated GD pit, offering flexible adaptation to various architectural conditions.

- Load Capacity: The standard load capacity is 6 tons, but custom designs with capacities of up to 18 tons are also available, ensuring adequate capacity for different loading needs.

Optional Accessories and Custom Designs:

- Gap Sealing Installation: Gap seals reduce heat loss and prevent dust and other contaminants from entering the warehouse, contributing to a clean and energy-efficient working environment.

- Enclosure-mounted Design: This version allows the dock leveller to be installed as a standalone unit, offering a flexible solution for locations where the building’s structure does not allow for traditional installation.

- Split Bridge Plate: The split bridge plate design allows loading of smaller vehicles, such as light trucks, as the plate size and mobility are better suited to these vehicle types.

- Heat-insulated Version: Insulated dock levellers are ideal for use between refrierated warehouses and refrigerated trucks, as they minimize temperature fluctuations and energy loss.

- 500 mm Bridge Plate: The 500 mm extended bridge plate is suitable for bridging larger distances, increasing the flexibility and efficiency of loading processes.

- Color Options: Dock levellers are typically available in RAL 5010 color, but can also be ordered in any RAL color to match the client’s branding or the building’s color scheme.

Applications: Tilting bridge plate dock levellers are widely used across various industries, including logistics, warehousing, food industry, and manufacturing plants. Their versatility and customizability make them an ideal solution for different loading challenges, ensuring fast, safe, and efficient goods handling.

Frequently Asked Questions

What is a tilting bridge plate dock leveller used for?

It is designed to bridge the height difference between a loading dock and various vehicle platforms, allowing forklifts and pallet trucks to move safely and smoothly during loading and unloading.

Are these dock levellers compliant with safety standards?

Yes. All GD tilting bridge plate dock levellers comply with the EN 1398 European standard, ensuring the highest level of operational safety and reliability.

What is the standard load capacity of the dock levellers?

The standard version supports loads up to 6 tons. Custom solutions are available for heavier applications, with capacities up to 18 tons.

Can the dock leveller be installed in existing facilities?

Yes. Installation can be done in a concrete foundation using a built-in frame or as a standalone unit using a prefabricated GD pit or enclosure-mounted system.

What is the function of the 400 mm (or optional 500 mm) bridge plate?

The bridge plate creates a secure connection between the dock and vehicle, enabling step-free loading and preventing instability or damage to goods.

Are there versions suitable for smaller vehicles?

Yes. The split bridge plate option is specifically designed to accommodate smaller delivery vehicles such as vans or light trucks.

Can dock levellers be used in temperature-controlled environments?

Absolutely. GD offers heat-insulated versions designed for refrigerated warehouses and trucks, helping to reduce temperature loss and energy consumption.

What customization options are available?

Options include:

- Split bridge plate

- Gap sealing systems

- 500 mm extended bridge plate

- Heat insulation

- Custom RAL color finish

- Enclosure-mounted versions for flexible site integration

How do gap seals enhance performance?

Gap seals prevent dust, moisture, and cold air from entering the facility, improving energy efficiency and cleanliness, especially in food or pharmaceutical environments.

Request a quote