ESS Lifting-Transport Unit for Railway Vehicle Manufacturing and Repair (ESS)

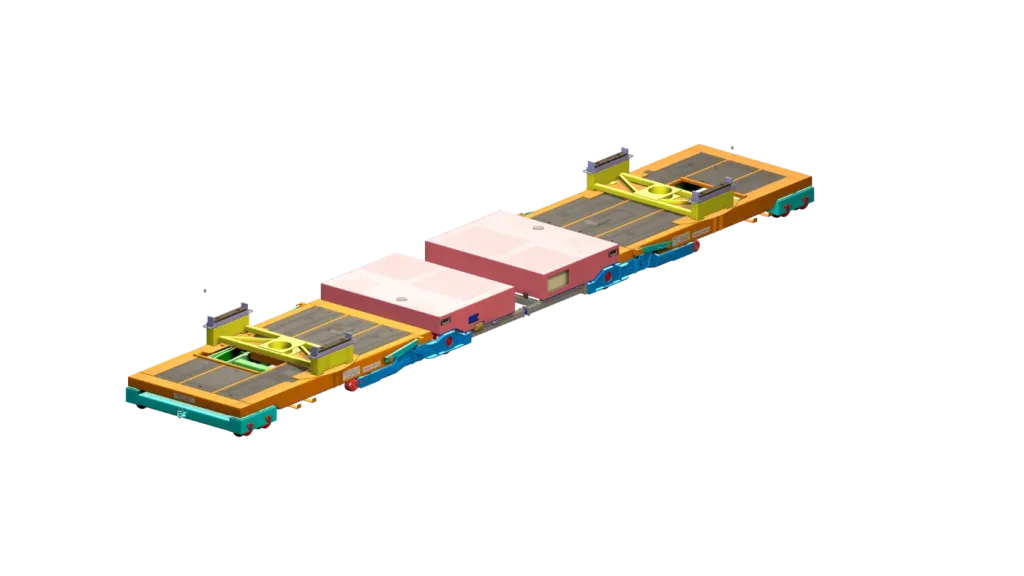

The ESS lifting and transport unit developed by GD Gép és Daru Kft. offers a high-performance, reliable, and safe solution for the complex material handling tasks in railway vehicle manufacturing and maintenance. This equipment is specifically designed for the precise and secure vertical and horizontal movement of railway car bodies – the vehicle frames – during the manufacturing, maintenance, and repair processes.

Versatile Functions – Lifting, Transporting, and Transitioning

The ESS lifting and transport unit has three main functions that ensure full coverage of the complex material handling tasks encountered in railway vehicle manufacturing:

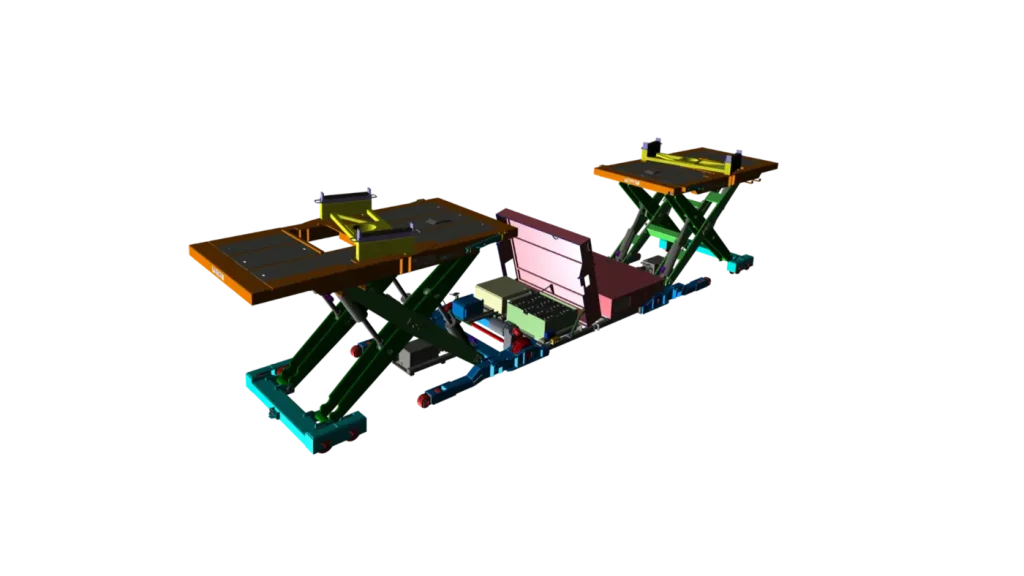

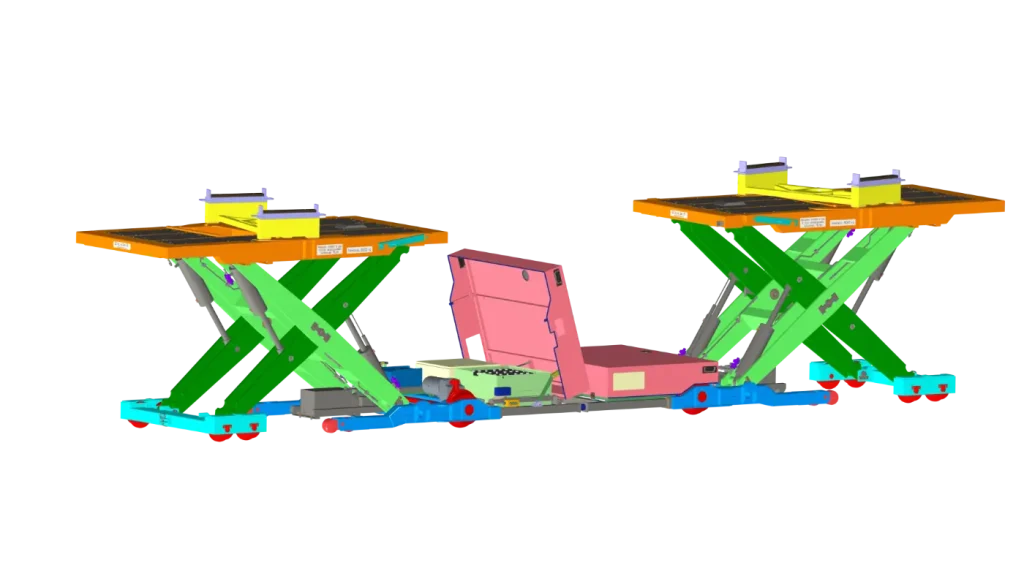

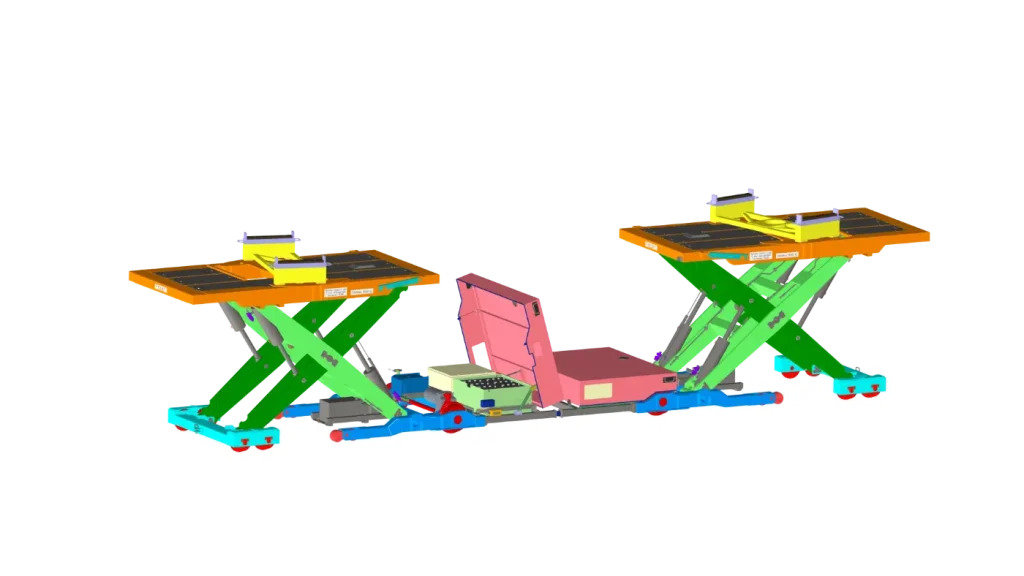

- Lifting: The unit is capable of vertical movement of the railway car body within a range of 800 mm to 1900 mm from the rail crown. This range enables the precise lifting of the vehicle frame for tasks such as assembly or inspection.

- Transporting: The horizontal movement of the car body occurs at a height of 800 mm, ensuring smooth and safe transportation between different working positions, even between assembly stations.

- Transitioning: The unit can move in its folded state (approximately 450 mm in height), allowing quick transitions between different work positions, optimizing operational time, and reducing downtime.

Sophisticated Motion Control – Precise and Safe Operation

The ESS unit features two main movement forms, both powered by electric drives:

- Vertical movement (lifting and lowering): Controlled by an electrohydraulic system with a single-speed, synchronized movement, independent of the load size. This guarantees outstanding stability and safety, especially for heavy loads.

- Horizontal movement (straight-line progression): Powered by a motor drive with a two-speed mode, which can be adjusted flexibly for transport tasks, even for long-distance movements.

Two Machines, One System – Synchronized Operation

The system consists of two self-propelled, electrohydraulically driven units, designed to operate on standard gauge railway tracks. Each unit has its own battery, hydraulic power unit, and undercarriage, enabling fully independent operation while maintaining synchronized functionality.

The control is done via a radio remote control, providing the operator with convenient, safe, and precise control. Continuous radio frequency communication between the two units ensures perfect coordination during the lifting and transport processes. The central control cabinet and radio receiver are located on one of the units, making the system compact yet efficient.

Main Advantages of the ESS Lifting and Transport Unit:

- Specifically designed for railway car bodies

- Wide lifting range (800–1900 mm)

- Horizontal movement at 800 mm height

- Easy transition in folded state (450 mm height)

- Electric and hydraulic self-sufficiency for both units

- Controlled lifting with load-independent operation

- Radio remote control with synchronized operation

Frequently Asked Questions

What is the ESS Lifting and Transport Unit used for?

The ESS Lifting and Transport Unit is designed to handle complex material handling tasks in railway vehicle manufacturing, maintenance, and repair. It is specifically built to lift, transport, and transition railway car bodies (vehicle frames) during these processes.

What are the key functions of the ESS Lifting and Transport Unit?

The ESS unit offers three main functions:

- Lifting: Vertical movement of the car body ranging from 800 mm to 1900 mm, enabling precise lifting for assembly or inspection.

- Transporting: Horizontal movement of the vehicle body at a height of 800 mm, allowing smooth transportation between different workstations.

- Transitioning: The unit can fold to 450 mm in height, enabling quick transitions between work positions, optimizing efficiency.

How is the ESS unit controlled?

The ESS unit is controlled via radio remote control, ensuring precise and safe operation. The two self-propelled units communicate using continuous radio frequency, ensuring synchronized operation during lifting and transport tasks.

How does the ESS Lifting and Transport Unit operate?

The system consists of two self-propelled, electrohydraulically driven units, designed to operate on standard gauge railway tracks. Each unit is independent, with its own battery, hydraulic power unit, and undercarriage. They work in sync, ensuring reliable and precise operation.

What are the movement options of the ESS unit?

The ESS unit has two main movement forms:

- Vertical movement: Powered by an electrohydraulic system for lifting and lowering, independent of the load size, ensuring stability and safety.

- Horizontal movement: Powered by a motor drive with two-speed modes that can be adjusted for various transport tasks, including long-distance movements.

What is the lifting range of the ESS unit?

The ESS Lifting and Transport Unit can lift the railway car body within a range of 800 mm to 1900 mm from the rail crown, ensuring precise positioning for various tasks.

How does the ESS unit transition between work positions?

The unit can be used in a folded state, with a height of 450 mm, allowing it to quickly transition between different workstations and optimize operational time.

Request a quote